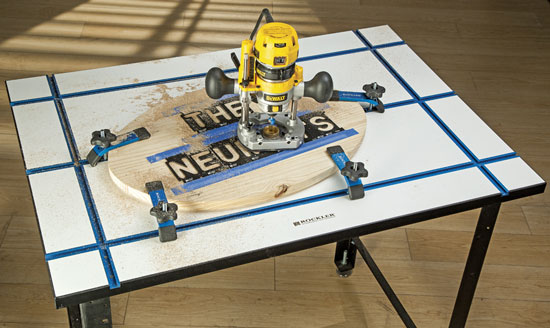

Rockler just came out with a new T-track tabletop that is made from a 40″ x 28″ x 1-1/8″ slab of melamine-coated MDF and several lengths of their universal T-tracks. An optional steel shop stand allows you to get up and running quickly and easily.

The tabletop is equipped with 5 intersecting T-tracks, 3 that span its length and 2 that span its width. This should give you reasonably good clamp and jig positioning flexibility. You can probably build in additional T-track sections, such as if you mainly work with smaller workpieces, but if you do that you may as well just build your own tabletop.

Advertisement

Rockler’s universal T-track accepts 1/4″ and 5/16″ T-bolts, as well as standard 1/4″ hex-head nuts and bolts. This means you can use a wide range of available clamp and jig components, or you can make your own fixtures.

One thing to note is that all 6 T-track intersections are interconnected, allowing you to slide a clamp or fixture anywhere it’s needed without having to remove it to go from one track to the next.

The tabletop is edged with 3mm black banding, and has a steel base that connects quickly to Rockler’s 36″ x 24″ shop stand, or your own.

Pricing is at $230 for the T-track tabletop, and $160 for the shop stand.

Buy Now(via Rockler)

Build Your Own(via Rockler Components)

Advertisement

Matthew

Wow, sure is pricey for something I can make myself…….

colin

How much to make me one? 😉

fred

Back in the late 1970’s I built a walk-around bench/assembly table with a 4 x 8 maple top, 2 end vises and 2 front vises. I bored a batch of dog holes lined up with the vises at intervals corresponding to the vise screw-travel. These were then the typical way to hold pieces using the push-up or flip up dog on the vise along with movable dogs to hold work in line with the vises. To hold down other pieces I bought tap-in / tap-out holdfasts to use in the dog holes – and a couple of sets of Record/Marples (M146) screw-type holdfasts that can be dropped into cast iron collars that are set in the middle of the bench. If I’m painting a picture of many days of work to complete this project – I’m doing so to compare it to the modern-day alternative offered by Rocker and others who supply T-track. While a Melamine / MDF table may never replace my big woodworking bench – I’ve built jigs with T-Track hardware and melamine to hold various projects for glue-up – making face-frames etc. Interestingly – I usually leave a bit of room at the margins (sans melamine) to use my bench holdfasts to hold these jigs securely on top of my bench. I’m not sure what the cost is now to the T-Track and the intersection pieces – but when I made my jigs intersection kits were about $20 each, and the track was about $6/foot. Cutting dados in melamine covered board – was rather easy for me – since I had access to a sliding table saw with both a dedicated scoring blade plus a dado set.

Dennis

Well this just becomes a fun little logic puzzle doesn’t it? From the picture, there are 6 intersections. From Rockler’s data the intersections are 6″ long. So each horizontal run is 40″ – (2×6″) = 28″, you need 3 of those. And each vertical run is 28″-(3×6″) = 10″, you need 2 of those. The intersections cost $22 and you need 6, so $132, and then you need 1×48″ (2×10″ + 1x 28″), $26. Then you need 2 more 28″ segments so you have 2 buy 2 36″ segments at $19. So all together $196 of hardware before Melamine and labor. Now I think I worked out the most efficient combination of segments to use, and I’m not taking into account the part of the track you lose to the saw blade. I’m sure someone will check the math, and let me know if I’m wrong.

So if you can get a 40″x28″ piece of Melamine, run dado’s in it, and mount the hardware for under $34, and your time is not worth anything to you (or you find this sort of thing more enjoyable than your time is worth) get cracking…

Stuart

Rockler sells the 28″ x 40″ table top plain, for $100.

Theoretically, this can be built with 2x 28″ lengths and 3x 40″ lengths which can be intersected via miter saw or chop-saw miters. (Cost of non-ferrous blade not included in calculations).

T-tracks are sold in maximum lengths of 4ft. 3ft lengths are actually slightly cheaper per foot when all are regularly priced. At times, 4pt kits might be the better buy.

If building this myself, I would use 3x 36″ lengths for the horizontal spans, and 3x 36″ lengths for the vertical spans. Total price would be $114.

The table as-shown requires 176″ of non-intersecting T-track, and 5x 36″ lengths provide 180″ of linear track. I would add a 6th 36″ track, or perhaps a 24″ track, just in case.

So that’s $100 for the table surface, and $95 for the T-track best case with 5x tracks, or $114 for 6x tracks. So that’s $195 or $214, plus some screws and a bunch of measuring, dado-ing, cutting, and mitering.

If more than 5x 36″ tracks are needed, 4x 48″ T-tracks are a better option – 196″ for $104 regular price.

DIY cost savings increase if a different or existing tabletop material is selected and used, and if T-tracks are purchased on sale.